ILFORD Y5 7*168m NIF

- Commodity name: ILFORD Y5 7*168m NIF

- Description

-

1. Overview

ILFORD industrial radiographic films are available in three types: Y4, Y5, and Y7. They are characterized by high sensitivity, high contrast, high definition, and fine grain images. They can be used directly or in conjunction with lead intensifying screens for exposure to X-rays or γ-rays. They are suitable for non-destructive testing in various fields, including electronic components, composite materials, casting and welding, shipbuilding, national defense and nuclear industries, and aerospace.

2. Film Classification

Standard/Film Type GB/T19348.1 EN 584.1 ASTM E 1815-06 ISO 11699-1 Y4 C3 C3 Ⅰ C3 Y5 C4 C4 Ⅰ C4 Y7 C5 C5 Ⅱ C5 3. Processing Methods

ILFORD industrial radiographic films are suitable for both manual processing at room temperature and automated high-temperature processing.

Processing Method Applicable Liquid Temperature/℃ Developing Time/min Fixing Time/min Drying/℃ Replenishment ml/m² Manual D-19b 20±0.5 5±1 10 Natural Drying 300 Automatic Processing G-30 29±1 1.5-2 2 45-55 4. Product Packaging Specifications

Specification Inner Packaging (Sheets/Bag) Intermediate Packaging (Bags/Box) Outer Packaging (Boxes/Carton) 356mm×432mm (14 inches × 17 inches) 50 100 1 5(50) 3 or 4(100) 305mm×381mm (12 inches × 15 inches) 50 1 5 70mm×90M(Y7/Y4) 1 1 100mm×90M(Y7/Y4) 1 1 300mm×400mm(Y7/Y4) 100 1 5 '*Customizable according to customer needs'

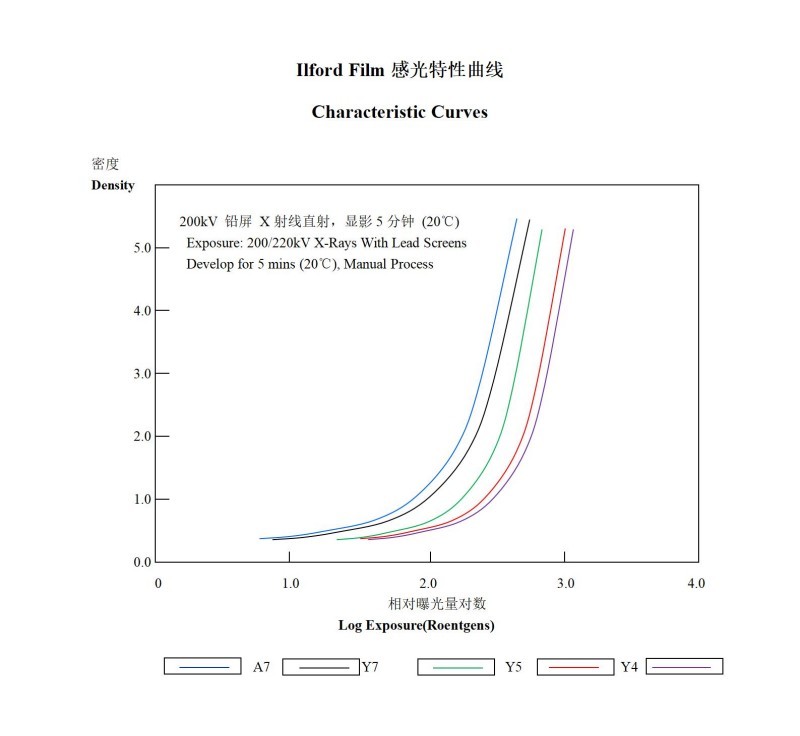

5. Film Characteristic Curve

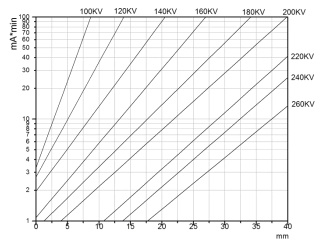

Y7 Film Aluminum Characteristic Curve

Y4 Film Aluminum Characteristic Curve

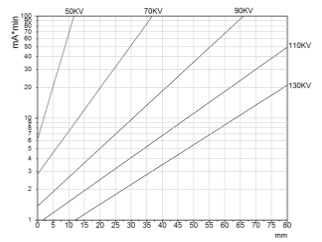

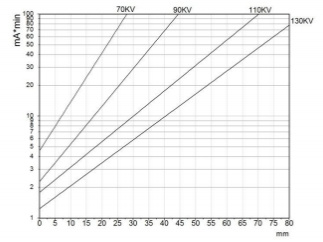

Y7 Film Steel Characteristic Curve

Exposure and Processing Conditions

Shooting Processing X-ray GE E320 Processor Protec PB 0.03mm Applicable Liquid LUCKY G-30 FFD 1m Automatic Processing Time 8 minutes Density 2.5 Developing Temperature 28℃ 6. Film Usage and Storage Conditions

The film needs to be unpacked, loaded, and processed in a darkroom. The safety light should be a dark red safety light, and the distance from the light should be at least 1.2 meters. The film should be stored in a cool and dry place. The optimal storage conditions are a temperature of 10℃~23℃ and a relative humidity of 30%~65%. Strictly avoid storing in high-temperature, humid, radiated, or chemically gaseous environments. Do not store with processing chemicals in the same room. Use within the expiry date.

7. Film Shelf Life

The shelf life of films stored under compliant conditions is 30 months.

Y7 Y5 Characteristic Curve

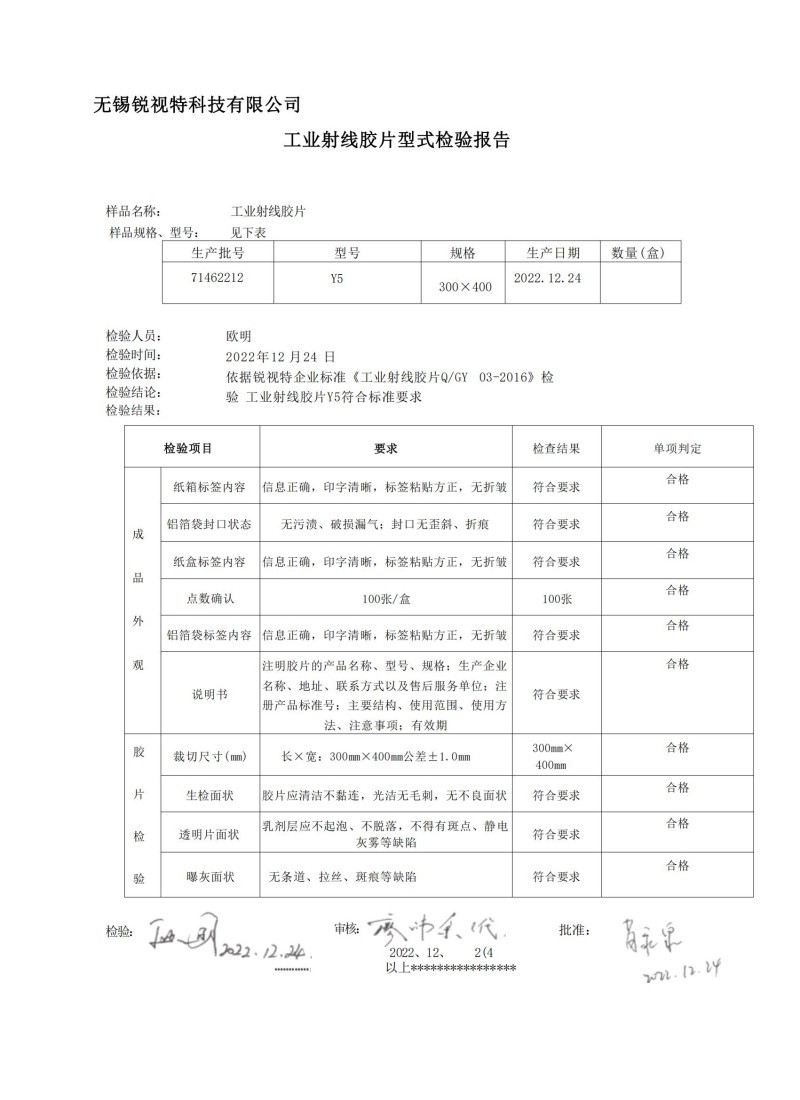

Y5 Test Report

Y7 Test Report

Message

Please provide the following valid information and we will contact you as soon as possible.