Baker Hughes CR

- Commodity name: Baker Hughes CR

- Description

-

Reliability, versatility, and performance in harsh non-destructive testing (NDT) environments

GE Inspection Technologies Business Group CRxThe Flex Computed Radiography scanner is flexible, reliable, features a wide dynamic range, and is easy to use.

CRxThe Flex is specifically designed for non-destructive testing, used in conjunction with isotopic or X-ray sources, and particularly suited for numerous applications in aerospace, oil and gas, power generation, and automotive industries.

Extended Computed Radiography RangeVersatility

CRxThe Flex scanner's ultra-wide dynamic range and high signal-to-noise ratio enable streamlined processes while improving part throughput. The wide dynamic range allows for the detection of a variety of thicknesses in a single exposure, making the CRxFlex an ideal choice for detecting casting and/or pipeline erosion/corrosion. This feature also reduces the number of exposures and retakes.

Flexibility

CRxAnother feature of the Flex is the ability to use it with hard cassettes (where the imaging plate cannot be removed from the cassette) or scan any shape or size of imaging plates up to 35x43cm (14x17 inches): round, triangular, rectangular, fan-shaped, etc. These custom sizes can be exposed using soft cassettes, then scanned using the CRxFlex.

Reliability

The robust CRxFlex occupies minimal desktop space and operates reliably in the most demanding NDT environments. Its modular internal design facilitates easy maintenance and provides a high mean time between failures (MTBF) and mean time to maintenance (MTBM) – maximizing uptime and minimizing downtime.

Horizontal Transport System

CRxThe Flex incorporates a state-of-the-art horizontal transport system with minimal or no direct contact with the imaging plate during scanning, thus preventing damage and/or wear to the imaging plates while scanning. The phosphor scanner can use imaging plates with soft cassettes as well as imaging plates in hard cassettes (for applications where the imaging plate does not need to be removed from the cassette), resulting in a longer imaging plate life.

Excellent Image Quality

Because the CRxFlex uses specially designed optical components, featuring true 50x50 micron pixels and unique 30-micron laser spot size, it ensures image quality with ultra-high IQI sensitivity. This excellent image quality has been proven by BAM certification, which rates the CRxFlex as IP Class Special/60 (ASTM E2446-05) and/or IP Class 1/60 (EN 14784-1) – ideal for weld inspection.

Rhythm® Software

CRxThe Flex is combined with GE’s Rhythm software, allowing users to acquire, view, report, and archive inspection data. The DICONDE-compliant Rhythm platform also features image enhancement and data sharing capabilities, significantly increasing productivity and enabling faster defect identification.

Applications

CRxThe Flex has a wide range of applications across many industries.

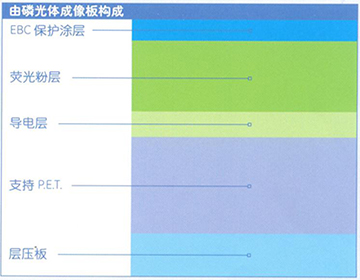

Imaging Plates

We offer different types of phosphor imaging plates. These plates have a special/patented protective layer that prevents scratches and damage. We can manufacture custom sizes and shapes up to 35x43 cm (14x17 inches) that are CRxFlex scannable and related inserts to meet your specific applications.

Reduced Retakes

Highly adaptable to changing exposure conditions with greater freedom in the selection of exposure dose.

Reduced Exposure Dose

In many cases, the imaging plate shows all diagnostic information in a single exposure.

Long Life

The imaging plates are protected with an electron beam cured (EBC) topcoat that provides optimum mechanical abrasion protection and excellent corrosion and oxidation resistance.

Image Quality

The composition of the phosphor material stored in the imaging plates ensures superior performance. This material has high absorption efficiency, excellent uniformity and a short response time, thus ensuring high sharpness and contrast.

Cassettes

GE cassettes are designed for NDT applications. CR cassettes are lightweight and easy to use. The cassettes use a high-strength, durable synthetic material.

Industrial X-ray uses higher energy radiation that standard medical cassettes cannot handle. Therefore, the cassettes are fitted with a built-in 250μm (0.010") front lead (Pb) screen and a 150μm (0.0006") back lead layer that ensures ideal backscatter protection and results in excellent image quality.

Technical Specifications – CRxFlex

Functional Data Processing Cassettes

(Cassettes/hour)35x43cm(14x17") 54/hour at 100μm 27/hour at 50μm 18x24cm(7x9") 80/hour at 100μm 40/hour at 50μm Multiple Plate Scanning e.g. 4x(6x24cm) or 4x(4.5x10") 216/hour at 100μm 108/hour at 50μm Laser Spot Size 30μm Scanning Resolution 50μm and 100μm Bit Depth 16-bit linear Image Buffer 256MB Certification CE, UL, RoHS, CCC, WEEE Size 693W×786D×497mmH(27.3W×30.9D×19.6"H) Weight 75kg(165lb) Interface FireWire(IEEE 1394) Electrical Parameters Voltage 100-240V AC, adaptive Frequency 50/60Hz Power Consumption 120W (standby), 320W (peak) Consumables Imaging Plate Size All sizes within 35×43cm(14×17") Custom Imaging Plate Size All sizes and/or shapes within 35×43cm(14×17") Cassette Size 35x43cm(14x17") 15×30cm(6×12") 18×24cm(7×9.5") GE Inspection Control Technology

GE Inspection Control Technology business is an industry-leading innovator in sensing and measurement, non-destructive testing technology, condition monitoring, and automated optimization control, helping customers achieve accuracy, efficiency, and safety. Its products are widely used in aerospace, oil and gas, power, transportation, and medical industries. It has more than 40 enterprises in 25 countries and belongs to the GE Oil & Gas Group, providing customers with more environmentally friendly, intelligent, and efficient solutions.

Message

Please provide the following valid information and we will contact you as soon as possible.