Fuji Industrial Digital Imaging CR

- Commodity name: Fuji Industrial Digital Imaging CR

- Description

-

Possessing keen risk insight and user-friendliness, providing reliable support for industry inspection

- —Through multiple functions such as automatic image quality adjustment and pipe wall thickness measurement, fast and high-quality inspection can be achieved.

- —Equipped with the traceability function (optional) of the digital X-ray imaging system stipulated by MAI*1.

- —Network solutions can be provided through supporting other systems.

*1: The efficient procurement procedure led by the US Air Force

Globally Leading Image Quality*2

Excellent image quality assurance key—advanced high spatial and density resolution and good signal-to-noise ratio (SNR)

The fusion of advanced technologies used by Fujifilm in image readers, software, and IPs provides high-quality images.

Reading resolution up to 25μm, advanced image processing, and high-matching IP. The fusion of Fujifilm's advanced technologies achieves the high image quality expected in digital imaging.

*2 Company survey data as of November 2012.

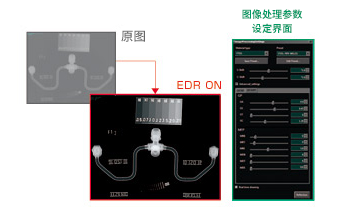

Advanced image processing and a wide dynamic range bring high-precision images to every inspection.

Automatically optimizes image quality according to the object and preset available parameters.

Since introducing the first digital diagnostic X-ray imaging system FCR in 1983, Fujifilm has developed imaging processing technology suitable for NDT objects. In DynamIx VU, we use the Exposure Data Identifier (EDR) to automatically adjust density and our proprietary image processing technology, Fujifilm Image Processing (FIP). With these technologies, optimized images of any test object can be provided. In addition, users can also customize parameter presets for image processing. Anyone can easily perform image adjustments suitable for the test object.

Wide dynamic range ensures a clear description of objects with different thicknesses.

DynamIx inherits Fujifilm's FCR technology, which has been at the forefront of film and digital image solution technologies. Within a wide dynamic range of 4 or more orders of magnitude, every part of the object, whether thick or thin, is clearly expressed without highlights, shadow blocking, or unevenness.

Innovative New Functions

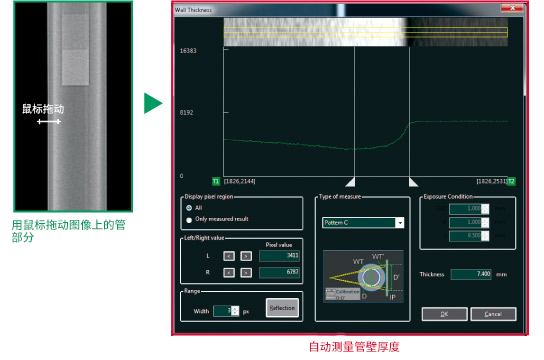

DynamIx VU*4Automatic measurement tools make corrosion testing easier

Automatically measures the pipe wall thickness, centering on the target area, achieving a more efficient and stable detection method.

Unlike traditional human eye measurement, Fujifilm automatically detects the outer wall and inner wall through precise image analysis technology, thereby automatically measuring the pipe wall thickness*3.

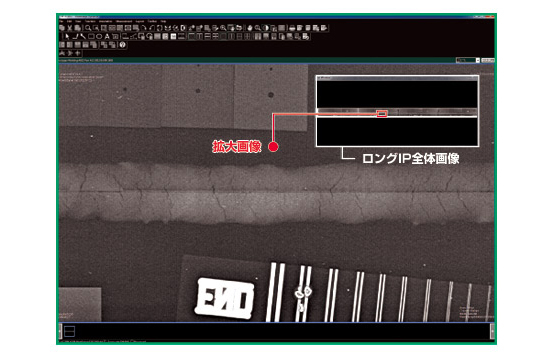

Long IP plates effectively expose welded pipe joints

Read images of special inspection screens using long IP plates.

Images can be read using IP plates up to 152 cm long, reducing the number of irradiations for a large amount of work.

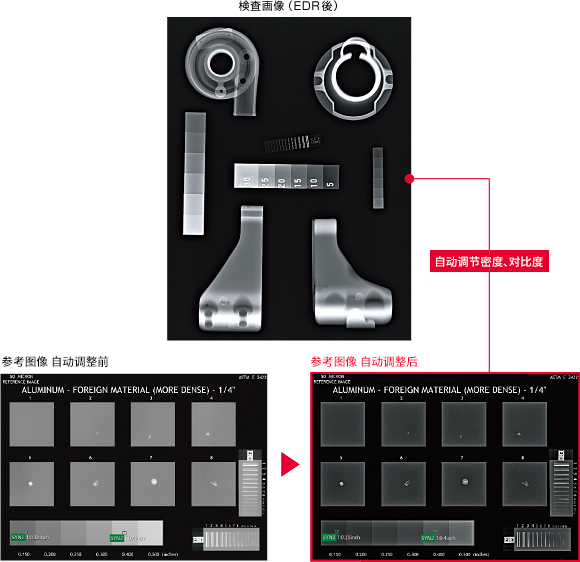

DynamIx VU Contrast Normalization* Automatically adjusts the reference image*5brightness to match one in the target image.

Standardization of inspections is easily achieved using ASTM digital reference radiographs and DynamIx VU software.

"DynamIx VU Contrast Normalization"*6 automatically adjusts the density and coefficient of the inspection image after EDR (Exposure Data Recognition) for various material benchmark images specified by ASTM*7 Standardization of inspections is easily achieved using ASTM digital reference radiographs and DynamIx VU software.

*3 Optional.

*4 The determination method complies with "HOIS (09) RP1".

*5 ASTM International (American Society for Testing and Materials: formerly known as the American Society for Testing Materials).

*6 Optional.

*7 As of August 2012, equipped with metal, aluminum, and titanium.

Work Efficiency

One-click mode switching, switch to the required working mode with one click.

Read and inspect on one computer.

The software allows reading and inspection on the computer and quick switching between screens. Access to the image database is also smooth, so that images appear immediately after reading. This feature improves the work efficiency of each process.

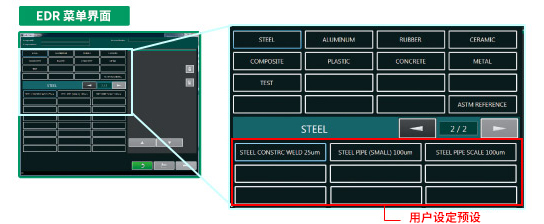

Density parameter presets allow for more efficient image adjustment.

Users can customize and preset automatic density adjustment parameters (Exposure Data Identifier: EDR) suitable for the test object. Density can be easily adjusted with one click.

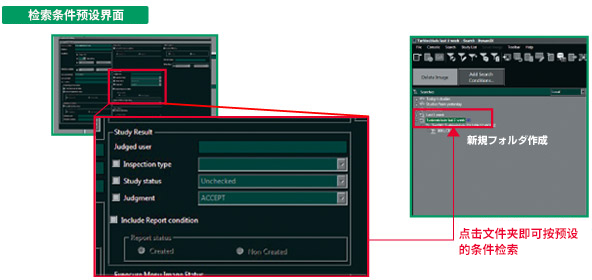

Fast data search based on initial conditions.

Frequently used search conditions can be preset, and data retrieval can be performed without entering input conditions each time.

More Reliable Evaluation and Traceability of Scale

Simplifies HR for image quality assessment. Easy to input defect determination results on special screens.

DYNAMIX VU newly provides DYNAMIX VU rating*automatic image quality assessment. This program calculates the image quality index based on the standardized signal-to-noise ratio (NSNR) of the image and evaluates whether the index meets the standard image quality evaluation indicators. This saves manual measurement and calculation In addition to ISO standards, it also supports industry-specific standards as evaluation criteria. A screen for inputting defect detection results is provided. Results can be recorded on the system.

Automatically records all evaluations to enhance reliability.

Each evaluation is recorded according to who, when, and what, which helps to enhance traceability.

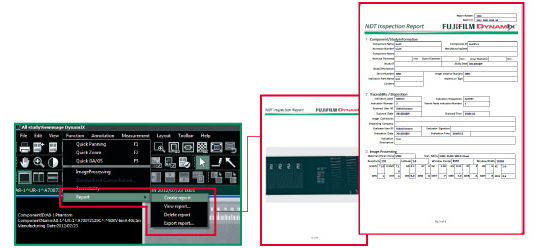

Create reports in a specified format with minimal data input.

After entering photographic conditions, image quality, and defect operation results on the reading and inspection interface, "DynamIx VU Report"*8 automatically generates a report in a predetermined format at the end of the inspection.

The report uses Microsoft Word format, making it easy to interact with Microsoft® software. Formats and file formats can also be customized.

*8 Optional accessories are supported.

Excellent controllability

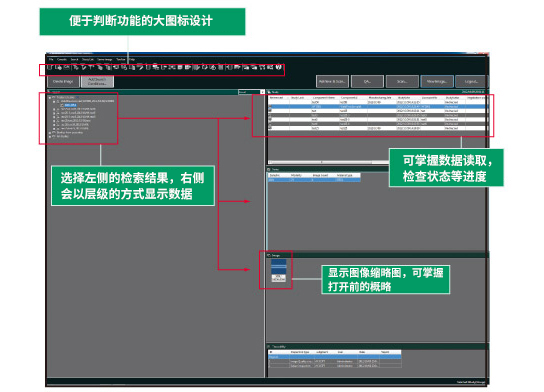

Full process visualization. Simple status management and data retrieval.

The data structure, content, and progress of each process are clear at a glance.

Ergonomically designed image display screen for easy viewing.

The interface focuses on ease of viewing and user convenience.

Network and Security

Inspection bases can also be networked. The system is optimized to adapt to the existing environment.

Networking and integration with other systems are possible.

The DynamIx system can be customized according to the existing network environment. By managing inspection image data from multiple sites on a central server, inspectors can access data from anywhere via the network to evaluate images. Connecting to an intranet or major ERP application allows a test request from one ERP package to be sent to each test site, or a test report to be received, and vice-versa.

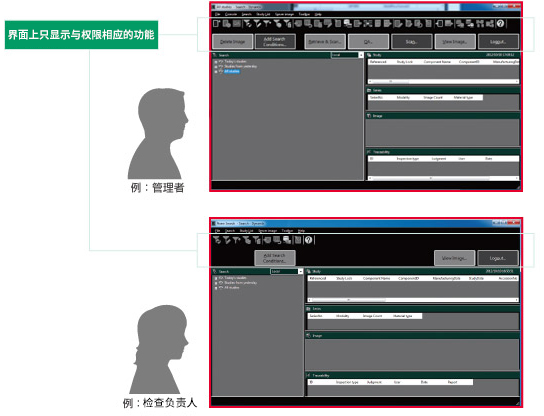

Security is enhanced through "access control." Only necessary functions are displayed, improving prevention.

User access to functions is controlled by the administrator.

The administrator can specify user access rights for each function to restrict viewing or editing of data and enhance security. With this function enabled, the system only displays functions relevant to the user, providing a simple and easy-to-use screen interface.

Message

Please provide the following valid information and we will contact you as soon as possible.