Is traditional X-ray photography technology 'old'?

Release time:

2020-07-10

Utilize a computer X-ray imaging system for fast and accurate non-destructive testing of printed circuit boards.

Using a computer X-ray imaging system for fast and accurate non-destructive testing of printed circuit boards;

Industrial radiography is a classic non-destructive testing technique, mainly used to help quality inspectors find internal defects or discontinuities in materials. Radiographic technology was discovered early on, with early applications mainly concentrated in the medical field. However, with the passage of time and the advancement of relevant scientific research, people have found that this technology has enormous potential for detection applications in the industrial field (especially manufacturing).

Now, metal products such as welded parts and metal castings often use radiographic technology for inspection. This technology provides convenience for manufacturers because it not only provides fast, efficient, and accurate product inspection results, but also does not sacrifice or damage any material properties, making it a truly non-destructive testing technique.

Today, with the increasing use of polymeric materials and the further development of radiographic testing technology, X-ray testing technology has become a reliable testing method for many plastic products, silicone rubber, microchips, and rubber products.

This testing method can complete rapid testing in accordance with various industry standards. Specific procedures and evaluation standards can be found in standards such as those prescribed by ASTM (American Society for Testing and Materials), ASME (American Society of Mechanical Engineers), and MIL (US Military Standard). Technicians who perform testing and evaluate samples usually need to have certificates issued by professional certification bodies (such as the American Society for Nondestructive Testing), because only qualified operators strictly following the testing requirements can ensure qualified testing results.

Industrial Radiography

Generally, X-ray testing can be performed using the following two methods:

(1) Computed Radiography (CR);

(2) Conventional Radiography (XR).

Using conventional radiography (XR), after exposure, a silver bromide-based industrial film (manual or automatic processing) is formed, and the photographed image is then checked to ensure sufficient image quality; then, the film is evaluated according to a certain standard.

Computed radiography (CR) uses a conventional X-ray imaging device to expose the image and create a digital file. This is mainly achieved by using a phosphor-based imaging plate instead of a physical film. The imaging plate is the core component of computed radiography, similar to the role of film in conventional X-rays. This method also has an additional advantage: the image can be adjusted to increase contrast, and specific areas can be zoomed in for observation.

Computed radiography can show details in a single exposure that film radiography shows in multiple exposures. Image source: Laboratory Testing

Both methods can obtain accurate test results with lower energy and in less time; this makes them very accurate and efficient for testing special samples.

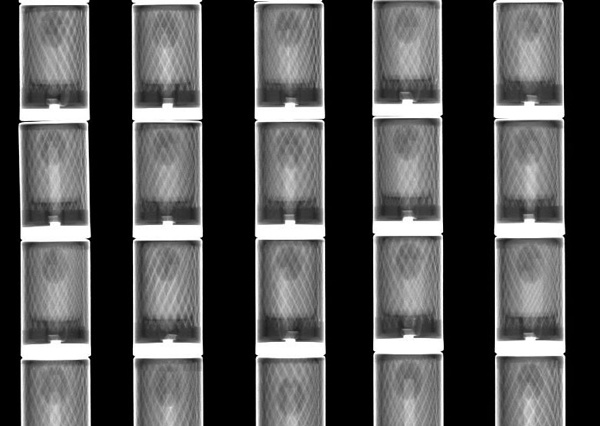

Electronic Product Inspection

In the manufacturing of transformers, transceivers, and semiconductors, X-ray radiographic testing technology is a very useful testing method. This technology can easily show whether there are defects such as fragments inside the test piece and other risks, and the test results are also independent, effectively reducing human interference factors.

Computed radiography can show details in a single exposure that film radiography shows in multiple exposures. Image source: Laboratory Testing

In many industries, computed radiography (CR) is relatively more effective because images obtained using this method are easier to transfer or share (e.g., between the testing party and the customer).

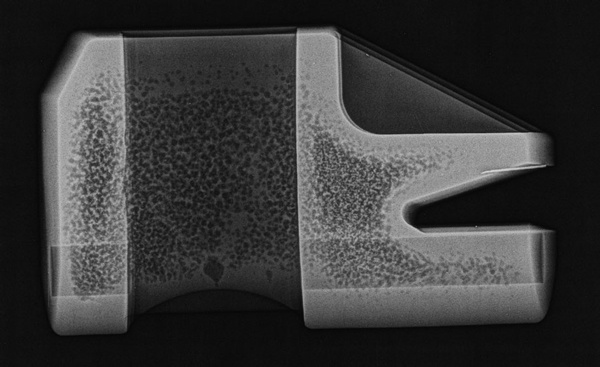

Plastic Product Inspection

Discontinuities in plastic produced during injection molding can be highlighted using radiography; Image source: Laboratory Testing

In recent years, the development and application of plastic products have become increasingly widespread, and the application of customized injection molding models has also become more common; injection molding is a widely used method for producing a large number of identical components. This technology has very strict tolerance requirements and does not allow defects or anomalies in the samples. X-ray radiographic testing technology is extremely effective for testing these samples and ensures a high pass rate for the final components. Depending on the specific needs, both computed radiography and conventional radiography can be used in this field.

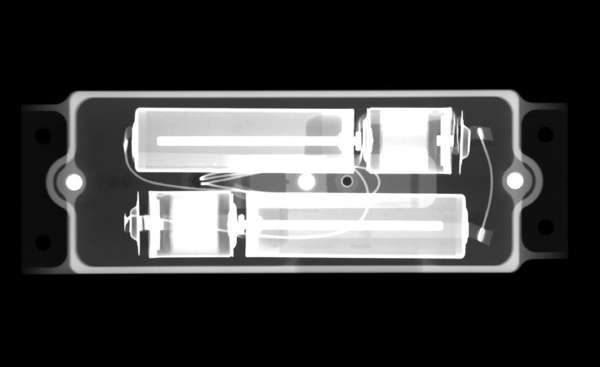

Lithium-ion Battery Inspection

Lithium-ion batteries are now frequently used in aerospace and defense applications; precisely because they are used in these high-end fields (spacecraft, weapons systems, electronic communications, etc.), these batteries require extremely high reliability.

X-ray radiographic testing technology can effectively detect whether these products are assembled correctly and whether there are defects or foreign objects inside. It is worth reiterating that this method is a low-cost, non-destructive testing method, which is particularly suitable for testing such high-value products.

Computed radiography can show details in a single exposure that film radiography shows in multiple exposures. Image source: Laboratory Testing

Depending on the end-user needs (e.g., many aerospace and defense projects require X-ray films that preserve record information), one of the computed radiography and conventional radiography methods can be selected. If it is not necessary to keep the film, computed radiography can be used to assist in the R&D and evaluation work of such batteries. The screen capture function of this method provides convenience for R&D personnel and helps to add radiographic images to relevant reports or instructions.

Applications in Fire Investigation and Legal Proceedings

Another unique application of X-ray radiographic testing technology is in fire investigation and legal proceedings; during the investigation, damaged objects (such as ceiling fans) are usually isolated for inspection. X-ray radiographic testing technology is used to obtain X-ray films of the test samples. By analyzing these films, it can be determined whether the substance is related to the fire. These images can be used as important evidence in court to determine which party is primarily responsible, etc.

In short, the use of X-ray radiography for non-metallic products (such as plastic parts) is showing a growing trend; the test results are obtained quickly and accurately. So, who says X-ray radiographic testing technology is "old"? It's still thriving and developing vigorously!

Related News